Disclosure: Microsoft is a client of the author.

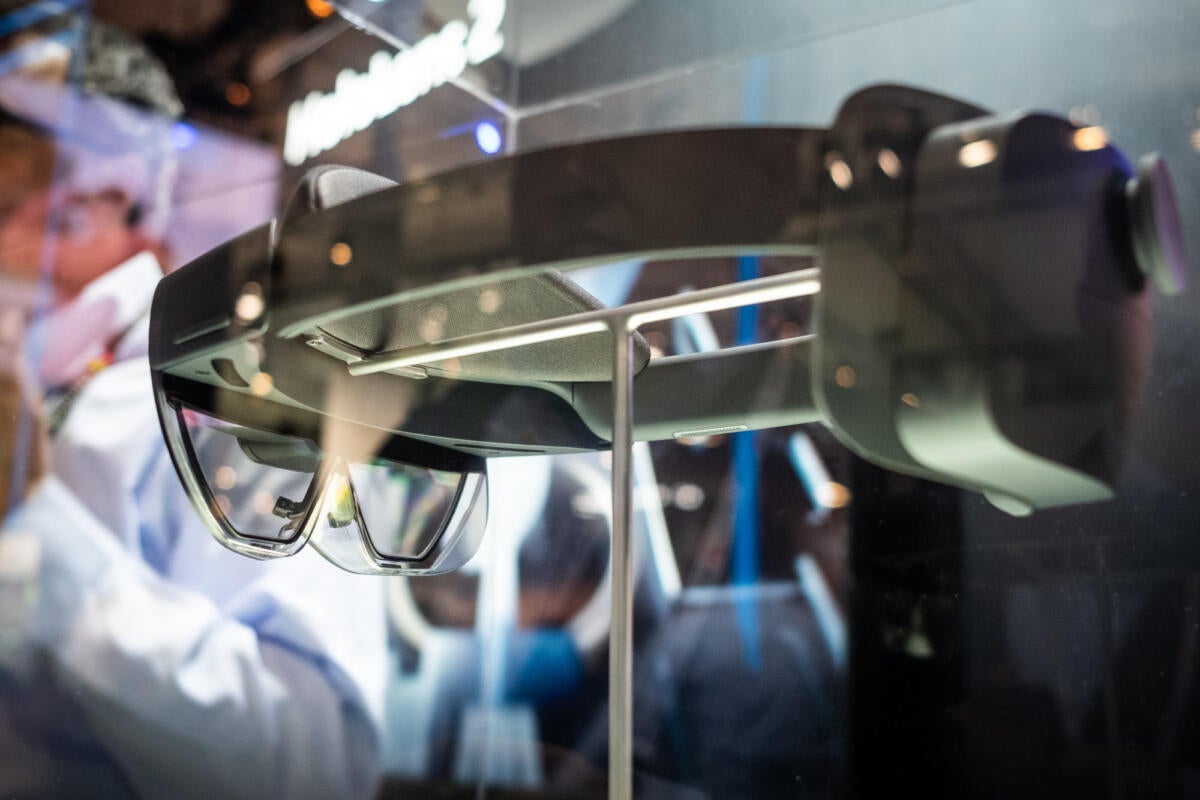

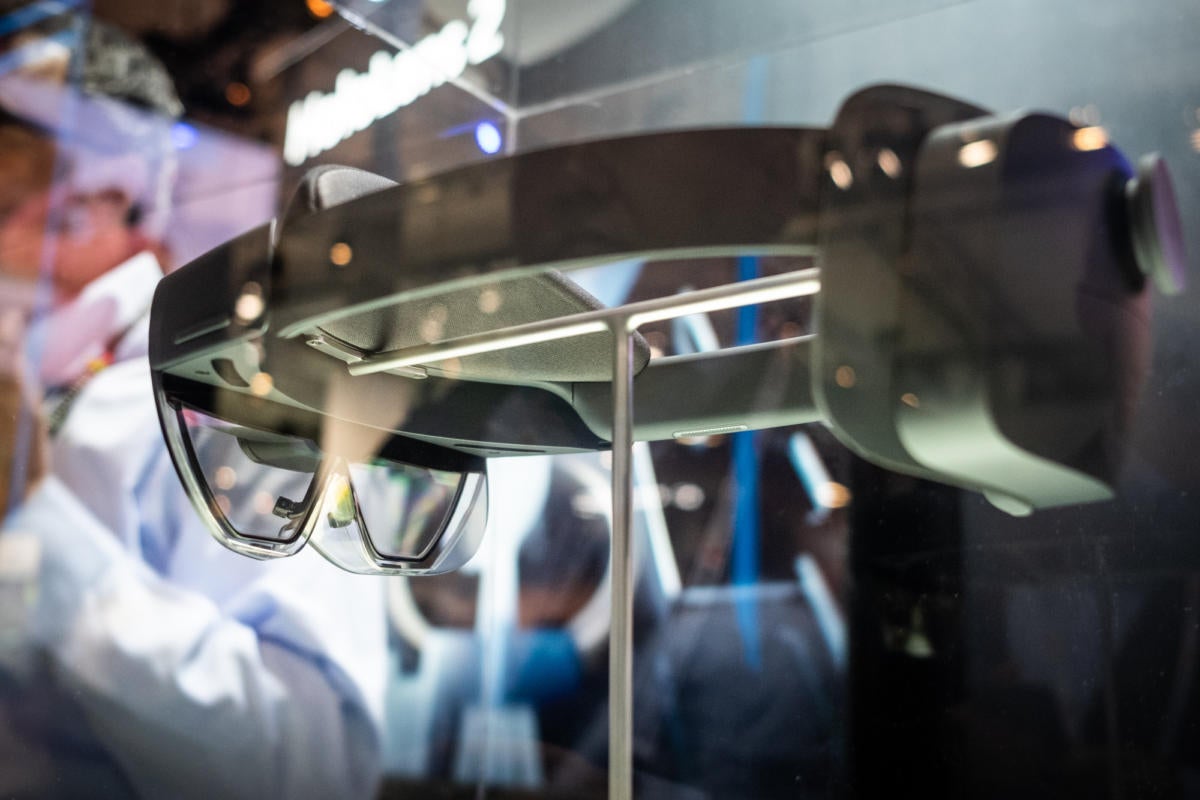

Mixed reality (MR) in the consumer market has been less than exciting, but it’s been a big hit in business — particularly in manufacturing and training. Lockheed Martin was one of the first companies to embrace this technology (along with other aerospace firms like Boeing). In a presentation this week, Lockheed Martin execs explained where the technology — which relies on Hololens — worked and where it could work in the future as it evolves. They also contrasted HoloLens I and II, saying the latter was far more useful over a more extended time.

The presentation revolved around the Orion Launch Platform’s assembly and reminded me of a story I heard from a professor who worked on the Atlas Launch platform. In his time, spaceships were triple redundant. The assembly team would get three parts for every central system. If the first part failed the test, they’d go to the second part; if it failed, they’d go to the third; and if it failed, they’d install the first part, relying on the redundant systems in case of failure in flight. (That was the instant I stopped wishing I were an astronaut.) I mean, what if it was a design failure?

As for Lockheed Martin, officials indicated that since the rollout of HoloLens, the systems that used it have had zero failures. So let’s chat about how the company reduced manufacturing overhead by up to 99% in processes where HoloLens was used successfully.

Where HoloLens wasn’t used

One of the more interesting parts of the presentation focused on where the MR technology wasn’t used and performed poorly. Collaboration has long been thought as a natural area for MR, but Lockheed did not mention this use. That’s likely because, despite the potential, we haven’t been working from home long enough, nor have the MR controls and experience advanced enough to meet the high expectations for this technology. The expectation is that meetings would be just like being there in real life. But MR currently falls well short of that; tools such as Microsoft Teams are increasingly seen as adequate for replacing in-person meetings — and they don’t yet use mixed reality. I’d expect this to change over time, but virtual space meetings are now more of a novelty than a real solution.

Peripheral vision limitations, both horizontal and vertical, limit the adoption of this technology in two distinct areas: workbench assembly, where an employee needs to see information screens above their workspace, requiring a greater vertical field of view, and full simulations (such as battlefield simulations) that require both vertical and horizontal view enhancements for better immersion. The trainee needs to learn to scan their environment for threats, and they can’t have their central vision obscured by anything.

Where HoloLens worked

Similar to the successes at Boing, Lockheed’s best use of MR technology was in final assembly. It uses the OODA process — Observe, Orient, Decide, Act — where the first three elements can take, on average, 51% of the assembly time. HoloLens could reduce those segments’ impact by up to 99% allowing workers to almost immediately move to assembly.

Assembly is the fun part, and several Lockheed Martin employees who were retiring asked to stay on after HoloLens was put into use. That’s because it changed what had been a tedious process into one that was far more enjoyable. The old saying is “better, faster, cheaper — pick any two,” but Lockheed said it could advance on all three vectors using mixed-reality technology.

The improvements came by automating many manual processes such as measuring, planning, and prioritizing the work. HoloLens could do all of that for the assembly tech and highlight where the part needed to go; rather than spending so much time planning, workers could put on the headset and start building. (I’d kill to have this capability for one of my car projects.)

Assemblers can also bring up virtual computer screens that allow them to see alerts, record progress, and better manage the project. Virtually eliminating half the cost of assembly while saving, on average, $38 per unit across two million units has made HoloLens a vast success at Lockheed. Execs also think it could have a considerable impact on other industries, like healthcare. Can you imagine reducing insurance premiums for hospitals by eliminating surgical mistakes, just as Lockheed eliminated assembly mistakes? And that’s on top of the training and ability to get remote support the device allows.

Wrapping up

Mixed reality is still in its infancy, but it is already having a significant impact on aerospace and, as the technology advances and people get more comfortable with it, it is poised to affect an ever-growing market across industries such as automotive manufacturing, healthcare, military, law enforcement, air travel, and even food. When you can become an expert by simply putting on a headset tied to AI, training and operational costs decline while quality, manufacturing time, and job satisfaction improve.

While there are other devices in the market, HoloLens stands out for the tools that surround it, which turn it into a complete solution. Some of those tools can be used with other headsets, but companies will want to review their ecosystem before making a decision on what to buy. Otherwise, you could end up with a great headset that doesn’t do what you need to do.

We are still at the front-end of what promises to be a significant productivity pivot. Still, firms like Lockheed and Boing are already reporting significant manufacturing and support benefits from mixed reality, with more on the way.